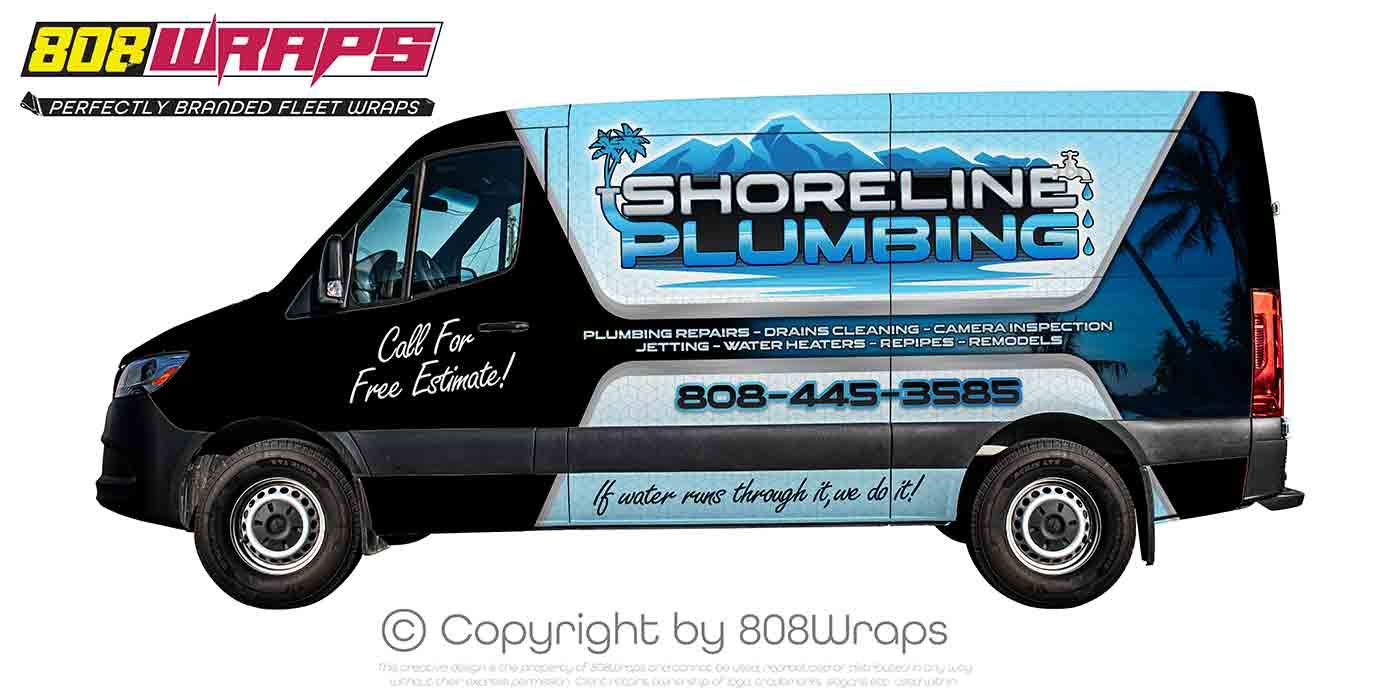

1. Design

When designing a typical business card, flyer, or postcard the user normally goes online to a “gang-run” style printer like VistaPrint or the many others and chooses one of 10,000 templates that other people have used, add their logo, contact information and they are done. They have designed their own business card . . .

However there are no boilermaker templates for vehicle wraps. Each one should be custom to the users requirements in order to meet their expectations. A great design will exceed all of the users wildest dreams. The wrong design will be their worst nightmare and a waste of their time and money.

The designer must be highly experienced and utilize the right tools by using the best vehicle wrap templates available in order to create a car wrap design that will fit a specific vehicle exactly. This is a crucial first step so that the proofs match the finished product exactly with no surprises in regards to alignment or placement of the content of the design onto the body of the vehicle.

Every angle, space, curve of the vehicle must be taken into consideration when designing a wrap. Ignoring these elements will result in a car wrap design that is not easy on the eyes nor is easy to read and understand. It will also have a negative effect on your company image.

808Wraps uses only the best templates available to ensure the proofs look like the finished product every time!

2. Material

There are many high and low quality vinyl manufacturers out

there. Top brand names that have been around for years and

offer the best car wrap vinyl include: 3M, Avery, Oracal and Arlon.

If you care about quality and longevity of the wrap then you want

to make sure that a high quality vinyl is being used.

You also need to keep in mind that simply stating that a 3M vinyl

is being used it doesn't mean that particular vinyl is the right choice for your project. 3M and all other

manufactures offer many different types of vinyl from high-quality, high-cost Cast Vinyl to lower

performance, cheaper Calendared Vinyl.

The combination of the vinyl and the over-laminate is also extremely important. More often than not shops will use a 3M Cast

vinyl but will use a Calendared or cheaper Laminate to reduce the cost. Cast laminates are about three

times the cost of calendared. Even a trained eye can not tell the difference between the two at first but

as time passes the calendared laminate will start to fade much faster than a cast. Also a calendared

laminate is not designed to be used on vehicle curves and it will bubble and pop out of its position within

the first few months.

So as you can see materials play a very important role in a vehicle wrap, you can have the best design

and the best installer but with the wrong material your wrap won't last. 808Wraps uses only Avery MPI 1005 EZRS cast vinyl with matching over-laminate in ALL of

its vehicle wrap projects.

Regardless if we are wrapping a Lamborghini or a box truck we choose to use the best materials to avoid issues in the long term.

We want our clients to get the greatest return on their investment possible.Why re-wrap a vehicle every 1-3 years when you can use a better material and re-wrap every 4-5 years?

3. Production

Let's say you have the perfect design and are using the best suited

vinyl or materials for the job.

Now is time to print your design on the vinyl. Using a

wide format digital printer is not as simple as using a desktop or office printer that we all use at home or office. There is a lot more

knowledge required by the designer and production person when printing a vehicle wrap

Each manufacturer's vinyl has its own unique print profile. The printer software must be setup properly to recognize all the different medias that a print shop may use in the production of their wide format printed materials. What is a

print profile you might ask? Simply put it's a code specifically created for that particular vinyl

which tells the printer exactly how much ink to lay on the vinyl in

order to get the best results.

Many print shops don't bother with this step and tend to use one

profile for all media. This results in dull, over or under saturated

images that just don't look right. 808Wraps has been in the printing industry for 20+years and has all the knowledge and experience to make sure the colors come out exactly as show during the proof and design process.

We also offer proof samples upon request free of charge in order to meet the needs of color specific projects.

If you have any concerns we will make a proof on the actual material and lamination so there are no surprises with the final product.

4. Preparation

Let's take this a step further, you have the

perfect car wrap design, the best material

and a great print. Now it's time to get your

vehicle readied for the installation.

The most time consuming part of wrapping a

vehicle is the prep process. This is where the

installer has to go over every inch of your

car's surface as well as under the weather

trims, cracks, fenders to make sure they're

100% clean & wax free.

The car must be washed the day before &

has to be dry. A special solution is used to

wipe the car down completely to make sure any wax residue has been removed. Then again, using alcohol the car has to

be wiped down to make sure the solution that was used to remove the wax has been removed otherwise it will affect the

adhesive of the vinyl.

The smallest dirt left behind could result in the vinyl's adhesive to fail and after a short time, lift off the surface. A small lift

will allow water to get under the wrap and eventually cause the entire wrap to fail.

Since this is the most time consuming part of the wrap it is also the least favorite part of the job for an installer

and therefore most overlooked.

808Wraps is the only vehicle wrap company in Hawaii that sends a specialized mobile auto detailer to you the day before the install. The detailer has extensive experience in preparing the body of vehicles for wrap installation. They focus on de-waxing the surface of a vehicle. Removing any substances that have been used in the past cleaning process that may contain ammonia, bleach or other adhesive removers. They remove any tar and thoroughly inspect the body of the vehicle again for any dents, rust, or other issues that could affect the quality of the install.

This way the vehicle comes fully prepped on the day of the install. Then the installers will give it a final cleaning in preparation to make the surface cherry and fully primed to receive its new skin!

5. Install

Facility

Look how far we have come, you have your perfect design, the

perfect material, a great print and your vehicle has been perfectly

prepped... now you need a Car Wrap Facility.

The question now is where will the actual installation take place?

Indoor or Outdoors? Will the indoor facility be dust free and have

the right temperature required by the vinyl manufacturer during

installation?

If your wrap is being installed outdoor, well then you're off to a

terrible start. There is absolutely no way to avoid large and small

dust particles away from the surface of your car. The results can

be noticed right away because even the smallest dust particle will

show through the wrap and having thousands of them under your

wrap will look like a layer of sand was put down before the

wrapping of the car. This not only looks terrible but large enough

particles could cause holes and rips in the wrap and allow water to

leak behind the vinyl causing the wrap to fail.

If your vehicle is being wrapped indoors, well that's great, but the

indoor facility must be super clean with some type of dust control

and it must be at the right temperature. Installing a wrap at a high

temperatures will cause it to over stretch and fail over the

long-term.

So a dedicated installation facility is extremely important to

make sure the final outcome of the wrap is superb.

6. Installation

This is the last but not the least important step of a car wrap.

You have your perfect design, great material, superb print quality,

your vehicle has been prepped perfectly and the facility is

specifically designed for vehicle wraps.

All of these factors could be totally destroyed if an un-experienced

and unmotivated installer does the wrap.

Everyone seems to think that is easy to install a wrap, after all it

is simply a giant sticker right? ... Wrong!

It takes countless hours and a

lot of wasted material and money to learn the proper way to

install a wrap.

808Wraps installers are 3M Certified. It is like the Harvard Law School for our industry. You do not simply get the certification because you paid for the course. You have to demonstrate a solid understanding of wrap techniques and have the experience as well to pass. The certification process is over 10 days long with a grueling class schedule, and not all experienced installers pass on their first or even second time through the course.

Different materials behave differently and therefore the installer

must have extensive experience with various media. Many

installers develop their own tools for doing the job, and some

even get patented and adopted by other professionals in the

industry.

Although the actual installation of the wrap is very difficult,

the final trimming of the wrap is even more challenging.

You can have the perfectly installed wrap but if the excess

material is not trimmed and tucked properly the final outcome

will look terrible.

Trimming the wrap requires a steady hand, a lot of patience, experience and technique. This is what sets an excellent

installer apart from a good installer. Making the wrap to look like a paint job is what it's all about.

7. Post Installation

Now you might think well we're done, the wrap

has been installed and trimmed perfectly, I am

ready to enjoy my car... again wrong.

This is the step that is most overlooked by

installers because it is the most time

consuming and most boring part of the install.

The installer, now using a Heat-Gun (not a

torch), must go over the areas of the wrap that

is on a recessed or curved area, using a digital

thermometer to ensure every inch of these

areas reaches a certain degree as required

by the manufacturer. (Solid color wrap needs to reach a 45 to 50 degrees Celsius and printed media must reach

85 to 90 degrees Celsius).

NOW we are done, well almost done... let's say all the above factors were met and performed perfectly, what happens

if you still have issues with your wrap?

Customer service is the only thing you can depend on, so choosing a reputable wrap shop like

808Wraps becomes the most important part of your decision making process.

808Wraps offers the longest guarantee of all its work on Oahu, Kauai, Maui, and the Big Island. Most shops do not even warranty the material or the install and the longest we have ever heard of is 90 days. 808Wraps offers twice that with a 6 month guarantee agains lifting, fading, cracking of the vinyl. If you have issues simply let us know and we will resolve it on the spot.

808Wraps also offers the Ultimate Fleet Management Program

to its clients. For an extra $100 per vehicle per year if the vinyl becomes damaged due to any factor such as door dings, dents, accidents, etc we will send our installers on site to your location to minimize any down time for the vehicles and replace the damaged area at a 50% discount. This will ensure that any companies fleet will remain fresh and appealing to the viewers and put the companies best look forward on its fleet.

Contact an 808Wraps representative to learn more about wrapping your ride or to get a quote today.